Authors: Nandor Bodo, Andy Berry, Automotive Application Engineers, Manchester, UK

This interactive application note contains an embedded PartQuest Cloud simulation to augment the text.

To open the embedded simulation, simply hover over the simulation image. Left click anywhere in the graphic area once the central play button changes in colour from black to yellow. This opens the schematic in the PartQuest Cloud environment. See the interactive application note home page for more details on how to use the simulations. See accompanying application note: AN50003

1. Introduction

Throughout the evolution of modern engineering electromagnetic devices have taken prevalence in changing electrical energy to mechanical energy or movement. Most commonly we think about motors for such applications, however the humble solenoid is used even more often, thanks to its simplicity of construction and ease of driving. Solenoid coils are typically found in relays, contactors, and valves.

In the automotive sector solenoids are used for a range of applications, from starting the engine to shifting the transmission. Solenoids are used to activate four-wheel drive system, fuel injection systems, locking the doors of the car and controlling the air flow in the vehicle's air conditioning system. The vast number of valves in the vehicle are also controlled by solenoids.

2. Solenoid operating principles

Consisting of a fixed coil and a movable core or slug (termed the armature) the solenoids are able to push, pull or even do both as the current through them changes direction. The armature is used to assert mechanical force to the driven system. The motion is usually reversed by a spring that is attached to the core. The armature movement changes the inductance of the coil, which in turn acts as an electromagnet. The magnetic force applied to the armature is proportional to the change of this inductance and the current flowing through the core, as shown in Fig. 1.

From the electrical viewpoint, the solenoid acts as an inductive component, consisting of multiple wound coils. The current flowing through them creates a magnetic field. The sluggish nature of this highly concentrated field creates a voltage (termed Electro Motive Force, EMF) that opposes change in the magnetic field, and therefore in the current as well. In this way as voltage is initially applied to the solenoid coil the current starts rising gradually. The magnetic field, and therefore the force applied to the armature rises until it reaches a point where it is large enough to move the armature in the desired direction.

Because of this slow response, it is prudent to apply a high voltage to the solenoid at the start of its actuation to initiate a faster current response. As the armature starts moving, the solenoid’s inductance (as a function of the armature position) and back EMF (as a function of the armature speed) rise, limiting the rate of rise of the current.

Once the movement of the coil is mechanically prevented as it reaches its intended resting point, the back EMF diminishes. At this point the current continues to rise until only the coil resistance limits its value. This current can be quite high for the power supply, which is normally a battery in automotive applications

As the system has reached a mechanical steady state the amount of force needed to maintain this state is much lower than for moving the armature. Besides, the armature is usually part of a magnetic circuit with an air gap.

This air gap is closed by actuating the solenoid and moving the armature, therefore rendering the magnetic reluctance (equivalent for resistance in electric circuits) very small. This in turn allows the magnetic field flux (equivalent to current in electric circuits) to flow in abundance, increasing the applied force to the armature.

For the above reasons it is advisable to decrease the applied voltage to the solenoid after its armature has reached its intended position, to limit the applied power and avoid depleting the vehicle battery.

Idealised voltage and current waveforms are shown in Fig. 2.

3. Current regulated solenoid drives

A more recent approach to controlling solenoids uses current control as shown in Fig. 3.

The waveform is known as the “peak-and-hold” current waveform, predominantly used in Fuel Injection applications. Initially, the current is increased rapidly to a high value during the Boost Phase. The current can be allowed to reach high values at this stage, since it will provide the initial push for the armature to begin its journey. The slope of the current should be high and, therefore, the applied voltage should be high as well.

In the Peak Phase, for a time period sufficient for the armature to take its final position the current is held at a certain value. Then the current is reduced during the Bypass Phase. The rate of decrease of the current is dependent on the reverse voltage applied to the inductor in this phase. The current is set to a lower value during the Hold Phase. Therefore, the force applied to the armature is reduced to a level sufficient to hold the armature in place. The losses are also reduced since this current can be substantially lower than the one applied in the Peak Phase.

Finally, once the control signal is withdrawn, in the End of Injection Phase, the current is left to decay to zero, leaving the spring to return the armature to its initial position. Once again, the rate of inductor current decrease can be influenced by the voltage that appears across the inductor. At this instant, the speed of current decay might be important for timing reasons. If the current decays slowly it is hard to predict the instance when the force of the spring will prevail over the magnetic force, as the mechanical properties of the spring and the whole mechanical system of the solenoid might change over time. Furthermore, for the same reasons the speed of the armature cannot be guaranteed. For some time sensitive applications, such as internal combustion engine injector drive, such timing differences might prove to be crucial.

4. Discussion of simulation results

Four approaches to driving a current regulated solenoid are explored in simulations. The simulations had common control parts, for ease of comparison. The difference manifested in the power electronics driving the solenoid. The MOSFET driver logic relies on the current feedback being compared to its reference value. When the reference value is higher than the feedback, the MOSFET is switched at 1 kHz frequency. For the purposes of these simulations the solenoids were replaced by an inductor with 5 mH inductance.

4.1. Solenoid driver with free-wheeling diode

This is the simplest and easiest way to drive a solenoid. The inductive energy of the solenoid decays through a diode up to the battery voltage. The schematic is shown on Fig. 4 and the solenoid current and its reference is shown in Fig. 5

When the reference signal is received, at 10 ms, both MOSFETs turn on to ensure maximal current increase in the Boost Phase. Once the peak reference current is reached, the high side MOSFET is switched so that it controls the current around this reference value, which is chosen to be 3 A in the simulation. When the MOSFET is turned on the applied voltage equals to the battery voltage; when the MOSFET is turned off the current circulates through the bottom MOSFET and the bottom diode. The voltage applied to the inductor is equal to the voltage drop on these two elements, i.e. it is very low.

After the target time of 10 ms for the Peak Phase has elapsed, at 20 ms, the reference is changed to 1.2 A. Again, the top MOSFET is used to regulate the current. After the Hold Phase, at 40 ms,both MOSFETs are turned off and the current free-wheels through the two diodes, making the effective reverse voltage almost equal to the battery voltage. Considering a simple inductor voltage/current relation, with a battery voltage of 12 V and 5 mH inductance the duration of the End of Injection phase can be calculated to be close to 0.5 ms.

(Eq 1)

Both MOSFETs and diodes will need to withstand the battery voltage. Both MOSFETs and the top free-wheeling diode need to be rated to the reference Peak current, while the bottom free-wheeling diode conducts only the Hold current for a short amount of time. The dissipated energy was calculated for each component during the whole activation process. Comparison of the energies dissipated in each device for each topology can be found in Section 5. To obtain the power, the calculated energy value needs to be multiplied with the desired frequency of operation.

Compared to the other driver topologies, the free-wheeling driver is simple, has a low component count, but it is the slowest due to the inductor voltage being approximately equal to the battery voltage.

(Eq 2)

4.2. Solenoid driver with MOSFET avalanching

In this case there is no free-wheeling diode and the back EMF of the solenoid forces the MOSFET into avalanche mode of operation. Its schematic is shown in Fig. 6.

The mode of operation is identical to the free-wheeling diode circuit at the start. However, in End of Injection Phase, when both MOSFETs are turned off, the inductor current has no way to free-wheel. Therefore, the inductor voltage is increased until it breaks down the bottom MOSFET and drives it into avalanche mode.

This voltage is substantially higher than the battery voltage that was applied in the case of the free-wheeling circuit. Therefore, the current will decay faster. A close look at the MOSFET avalanche voltage and current can be seen in Fig. 7.

Consulting the inductor equation, (Eq 1), once again, with a voltage of 68 V, the End of Injection phase duration is now closer to 0.1 ms: a five-fold reduction compared to the free-wheeling case.

Once again, all the components need to be rated above the battery voltage and the target peak current. However, the bottom MOSFET needs to be repetitive avalanche rugged. The energy dissipated in each component is compared in Section 5.

Due to the high voltage of avalanche compared to the battery voltage, this method decays and therefore releases the solenoid faster. However, the energy of the inductor is now dissipated in the MOSFET in the form of heat. Therefore, careful consideration of a MOSFET is needed to handle this energy.

4.3. Solenoid driver with active clamp

This option is very similar to avalanche operation. Here a Zener clamp is connected drain to gate of the MOSFET, as seen in Fig. 8.

Once again, the circuit behaviour is identical as with the free-wheeling and avalanche circuits.

However, at the End Of Injection Phase as both MOSFETs are turned off and the inductor voltage starts to increase towards the bottom MOSFET VDS breakdown, the Zener diode starts conducting and pulls the MOSFET gate up forcing it into its linear region.

The MOSFET then maintains the sum of the Zener diode breakdown voltage, the diode forward voltage and the gate-source threshold voltage from drain to source.

In the previous case the MOSFET intrinsic diode has broken down in avalanche mode. In this case the current flows through the MOSFET channel.

As the MOSFET is in its linear region with large current and large voltage applied to it, there is an increased chance of hotspots and thermal runaway occurring if conditions are met. During active clamp there are high energy charge carriers generated in close proximity to the MOSFET’s gate oxide. These carriers might be injected into the oxide and cause damage.

Over many active clamp cycles the oxide can wear out and cause parametric shift and ultimately device failure. Currently it is not recommended to use MOSFETs in repetitive active clamp. Alternatively, repetitive avalanche is recommended as the long term reliability during repetitive avalanche is better defined. Simulated waveforms of the circuit behaviour are shown in Fig. 9.

4.4. Solenoid driver with Boost converter

This is the most complicated topology, shown in Fig. 10, with the highest performance. A boost converter, often operating at an output voltage in the range of 60 V, is used to charge and discharge the solenoid quickly (five times faster with five times larger voltage) during the Boost Phase and End of Injection Phase.

During the Peak and Hold Phases the nominal battery voltage is switched, as in the previous cases. This allows for fast actuation of the solenoid, but also the energy from the solenoid is regenerated into the DC link capacitor of the boost converter.

The cost here is the additional components to make the boost circuit, the additional PCB board space and overall higher voltage rating of the components. The added component count is reflected in the losses. However, it needs to be considered that the MOSFETs used in the Boost simulation are of lower current rating.

Simulations of solenoid drives

The simulation embedded in this application note have common parts, for ease of comparison. The difference manifests in the power electronics driving the setup.

Inside the block of the MOSFET driver logic the current feedback is being compared to its reference value. When the reference value is higher than the feedback, the MOSFET is switched at 1 kHz frequency.

The current reference is of a predetermined shape and is applied to all simulations in the same manner.

Click below to enter the simulation.

5. Summary of the topologies

Table 1 shows the losses encountered in each device for each topology, as well as their total loss. The MOSFETs used in the free-wheeling and active-clamped simulations were BUK9K13-60E, in the repetitive avalanche simulation BUK9K13-60RA and in the boost converter simulations BUK9Y38-100E, as these MOSFETs need to withstand higher voltages. Although the losses appear to be higher in the Boost topology, the recuperation of the energy means that it’s efficiency is on par with the free-wheeling topology, despite using higher RDSon components.

| Topology | Free-wheeling | Avalanche | Active clamp | Boost |

|---|---|---|---|---|

| Switching MOSFET (top) |

0.3 |

0.3 | 0.3 | 0.9 |

| Selector MOSFET (bottom) | 1 | 5.1 | 3 | 4 |

| Boost MOSFET | - | - | - | 0.03 |

| Switching diode (bottom) | 15.5 | 15.3 | 15.4 | 15.6 |

| Freewheeling diode (top) | 0.1 | - | - | 0.25 |

| 'OR' diode | - | - | - | 3.8 |

| Zener diode | - | - | 2 | - |

| Total losses | 17 | 20.7 | 20.7 | 26 |

Table 2 shows a summary of the pros and cons of the surveyed topologies. The avalanche and active clamp circuits are positioned between the low cost and low speed free-wheeling topology and the high cost and high speed boost topology. While there are risks in the longevity of the devices in the middle two topologies, Nexperia’s repetitive avalanche rugged components are extensively tested and their data sheets are equipped with the necessary data to make an informed choice and have the MOSFET last the full application lifetime.

| Topology | Free-wheeling | Avalanche | Active clamp | Boost |

|---|---|---|---|---|

| Cost |

Low |

Low | Low | High |

| Speed | Low | Medium | Medium | High |

| Efficiency | High | Low | Low | High |

| Reliability | Long term | Long term | Questionable | Long term |

6. How to select a repetitive avalanche rugged part

Existing MOSFET data sheets give scarce data about repetitive avalanching a MOSFET. The ones that do, give a very conservative rating. Nexperia’s repetitive avalanche products provide a way to objectively assess the suitability of the chosen part for the aimed application. From Fig. 7 the avalanche voltage can be read as 68 V, the avalanche current 1.4 A and the avalanche time is 0.1 ms. The inductance is 5 mH.

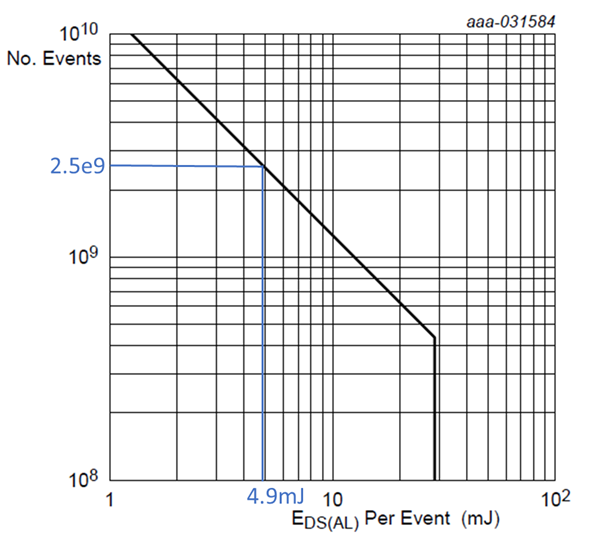

Let’s consider the BUK9K35-60RA. In the device data sheet, there are two figures (Fig. 11 and Fig. 12) that can help with choosing the device. From the avalanche current it can be seen from Fig. 11 that repetitive avalanche can be allowed to last for up to 0.2 ms. Eq 3 shows the amount of energy contained in the inductor and dissipated by the MOSFET:

(Eq 3)

This gives a value of 4.9 mJ. From Fig. 12 it can be seen that the number of cycles that can be allowed is approximately 2.5 billion.

We are left only to ensure that we are within the allowable junction temperature. As for the fuel injection frequency we can take a low value of 20 - 30 Hz, the junction temperature is of low concern as the MOSFET junction will have plenty of time to cool.

As these values satisfy the application requirements with small margins, a MOSFET with slightly higher current rating is chosen for the simulations.

7. Avalanche portfolio

Nexperia’s application specific FET portfolio for Repetitive Avalanche offers an alternative between the high-performance/high-cost boost and low-performance/low-cost freewheeling diode solenoid drives. The avalanching method has been possible using planar technology, however by technology optimisation, the Repetitive Avalanche products can comfortably handle reverse currents. The devices are tested rigorously for up to 1 billion cycles to ensure reliability.

Placed within the LFPAK package the device operating point is ensured to be below 175 ℃.

For more information please visit the links below:

- Application note AN10273: Power MOSFET single-shot and repetitive avalanche ruggedness rating

- Video: Selecting repetitive avalanche rugged MOSFETs

- Video: Repetitive avalanche rugged MOSFET applications

- Video: Driving solenoids in automotive applications

- Video: Driving MOSFETs in active clamp and avalanche mode – what is the difference

- Automotive ASFETs for Repetitive Avalanche product category page: Repetitive Avalanche ASFETs

PartQuest embedded Cloud simulations were used in this interactive application note.

| Page last updated 03 November 2023 |